Calcium carbonate, or limestone is one of Iran’s mineral products widely used in various industries such as papermaking, glass manufacturing, petrochemicals, pharmaceuticals, and food production. Below, we introduce the types, producers, packaging, and prices of calcium carbonate in Iran.

Types of Calcium Carbonate:

In general, two types of calcium carbonate are identified in Iran:

- Mineral Calcium Carbonate:

- Derived from the extraction of mineral rocks such as limestone, marble, gypsum, and chalk.

- This type has lower purity and whiteness, suitable for construction and industrial purposes.

- Precipitated Calcium Carbonate:

- Obtained through processing and micronizing mineral calcium carbonate.

- Exhibits higher purity and whiteness, ideal for sensitive and precision applications.

Producers of Calcium Carbonate in Iran:

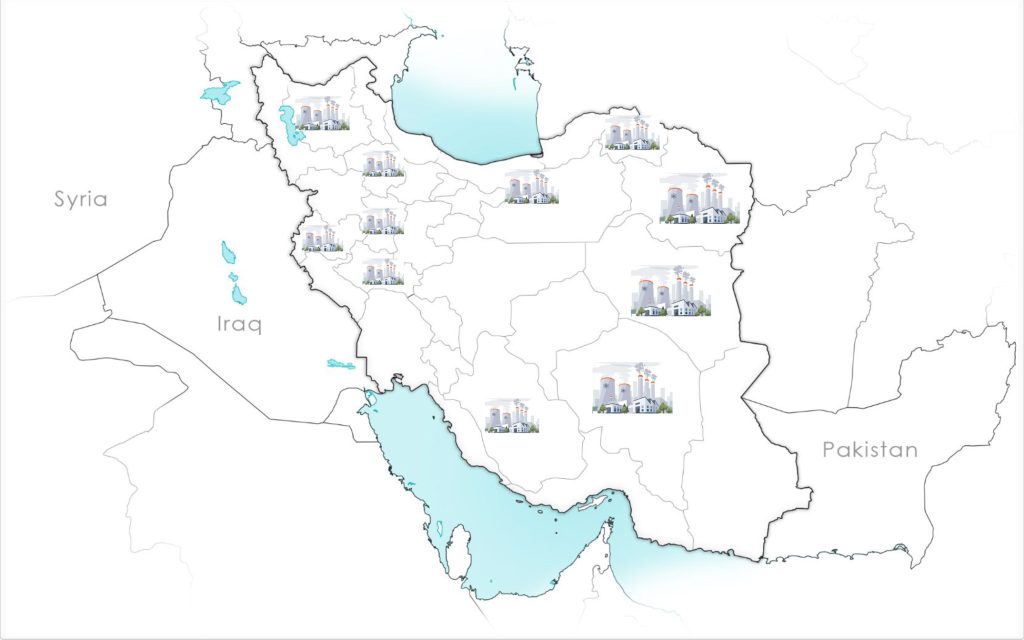

Iran stands as one of the world’s largest calcium carbonate producers, boasting rich reserves of this mineral. Statistics place Iran as the second or third global producer of calcium carbonate. Major production areas include Zanjan, Hamedan, Kerman, Razavi Khorasan, South Khorasan, North Khorasan, Alborz, Qazvin, Kermanshah, Lorestan, Fars, and East Azerbaijan.

Prominent companies and factories engaged in calcium carbonate production in these regions include:

- Golgohar Mining and Industrial Company (SIRJAN):

- One of the largest producers of mineral and precipitated calcium carbonate in Iran, located in Kerman province.

- Annual production capacity of 150,000 tons of mineral calcium carbonate and 100,000 tons of precipitated calcium carbonate.

- Arusha Powder Mining and Industrial Company (ZANJAN):

- A leading producer of precipitated calcium carbonate in Iran, situated in Zanjan province.

- Production capacity of 50,000 tons annually, offering high purity and whiteness.

- Sana Mine Mining and Industrial Company (HAAMEDAN):

- Among the oldest producers of mineral and precipitated calcium carbonate in Iran, based in Hamedan province.

- Annual production capacity of 30,000 tons of mineral calcium carbonate and 20,000 tons of precipitated calcium carbonate.

Packaging of Iranian Calcium Carbonate:

The packaging of calcium carbonate for export depends on the type and quantity. Typically, it is packaged in various weights ranging from 1 gram to 5 kilograms. Common packaging options include:

- Plastic Bags:

- Simple and cost-effective packaging suitable for lower-quality calcium carbonate.

- May impact purity and whiteness but serves basic purposes.

- Cardboard Boxes:

- Sturdy and resistant packaging suitable for higher-quality calcium carbonate.

- Preserves purity and whiteness, offering good aesthetics and suitability for transportation and storage.

- Wooden, Metal, or Plastic Crates:

- Very robust and durable packaging suitable for very high-quality calcium carbonate.

- Ensures the preservation of purity and whiteness, providing excellent aesthetics and suitability for transportation and storage.

- Glass or Metal Bottles:

- Elegant and attractive packaging suitable for high-quality calcium carbonate.

- Maintains purity and whiteness, offering excellent aesthetics and suitability for transportation and storage.

- Glass or Plastic Jars:

- Lightweight and efficient packaging suitable for medium-quality calcium carbonate.

- Preserves purity and whiteness, providing good aesthetics and suitability for transportation and storage.

This comprehensive guide aims to showcase Iran’s significant role in calcium carbonate production, emphasizing the diversity of types, prominent producers, and various packaging options tailored for different qualities of the product.